Understanding Electromagnetic Shielding Materials

Electromagnetic shielding materials are essential components designed to protect sensitive electronic devices from electromagnetic interference (EMI). Due to the proliferation of electromagnetic fields generated by modern technology, effective shielding has become crucial in various applications. In essence, these materials act as barriers that absorb, reflect, or attenuate electromagnetic waves, preventing unwanted signals from causing disruptions in electronic operations. For an in-depth exploration of electromagnetic shielding materials, it is important to understand their functionality, significance, and the types available.

What are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are specially designed substances that prevent the transmission of electromagnetic waves. This is accomplished through various physical and chemical properties that allow these materials to either absorb or reflect incoming electromagnetic radiation. These materials can be categorized based on their composition, structure, and intended performance characteristics.

Importance of Electromagnetic Shielding

The importance of electromagnetic shielding cannot be overstated in today’s technology-driven world. As electromagnetic fields are ubiquitous, they pose significant risks to electronic devices, especially sensitive equipment such as medical devices, communication systems, and military technology. Poorly shielded devices can lead to signal degradation, equipment malfunction, or complete failure. Moreover, for specific applications, regulatory compliance requires effective EMI shielding to safeguard against interference that could compromise device performance.

Basic Principles of Electromagnetic Shielding

The effectiveness of electromagnetic shielding arises from several principles, including absorption, reflection, and diffraction of electromagnetic waves. Material thickness, electrical conductivity, and magnetic permeability substantially influence the performance levels of these shielding materials. Key principles include:

- Absorption: Shielding materials absorb electromagnetic energy, converting it into thermal energy and preventing it from penetrating the shield.

- Reflection: Quality shielding reflects electromagnetic waves back toward their source, making it less likely for the waves to interact with sensitive components.

- Diffraction: This refers to the bending of waves around obstacles, which protective materials mitigate through their structural integrity and design.

Common Types of Electromagnetic Shielding Materials

Metals Used in Shielding

Metals are the most common materials for electromagnetic shielding due to their high electrical conductivity. Some of the most widely used metals include:

- Copper: Recognized for its excellent conductivity, copper is the go-to choice for many shielding applications. It effectively attenuates both electric and magnetic fields, making it invaluable in medical and aerospace industries.

- Aluminum: Lightweight and cost-effective, aluminum is often used in electronic enclosures. It provides adequate shielding against radio frequency interference (RFI).

- Steel: Steel, particularly pre-tin plated and stainless varieties, offers robust shielding capabilities along with durability, which is ideal for industrial applications.

- Nickel: Used primarily in specialized coatings, nickel enhances the conductive properties of other materials and is often integrated into composite shielding materials.

- Brass: With good corrosion resistance, brass is sometimes employed in connectors and RF applications.

Non-Metallic Shielding Options

While metals dominate the shielding market, non-metallic materials are gaining traction, especially in applications where weight and flexibility are critical. Key non-metallic options include:

- Conductive Polymers: These are organic compounds that conduct electricity and offer lightweight alternatives for EMI shielding, useful in complex geometries.

- Carbon-Based Materials: Carbon fibers or composites can be tailored for specific applications and provide decent conductivity for EMI purposes.

- Cement and Concrete: Heavy and dense, these materials can provide sufficient shielding in structural applications like buildings and bunkers.

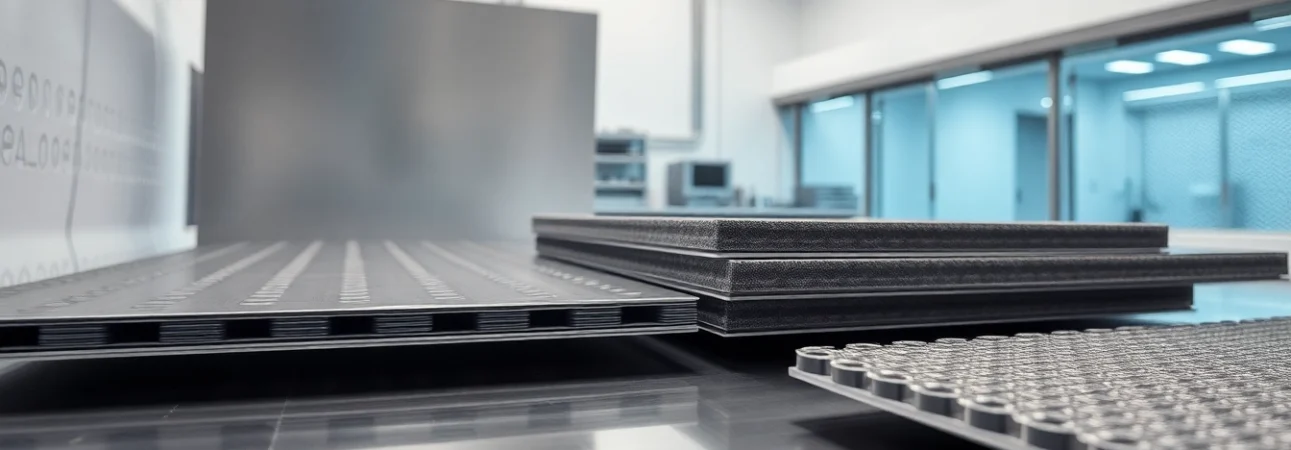

Composites and Advanced Materials

Innovation in material science has led to the development of composites that combine metals with non-metals for enhanced performance. Examples include:

- Metal Foams: Lightweight yet strong, metal foams have a unique structure that allows for excellent EMI shielding while reducing weight for aerospace and automotive applications.

- Nanocomposites: These materials leverage nanoscale materials combined with traditional substances to achieve superior electrical and thermal properties, ideal for miniaturized devices.

- Conductive Inks: Useful for printed electronics, these inks can create thin, flexible shields that are applicable to circuit boards and smart devices.

Applications of Electromagnetic Shielding Materials

Industry-Specific Uses

Electromagnetic shielding materials are widely used across various industries, including:

- Aerospace: Spacecraft and aircraft require comprehensive shielding to mitigate radiation and RFI, protecting delicate navigation and communication systems.

- Telecommunications: Antennas and communication equipment depend on robust shielding to maintain signal integrity and reduce cross-talk.

- Defense: Military applications often utilize multi-layered shielding solutions to protect sensitive electronic warfare equipment.

Consumer Electronics Applications

In the consumer electronics market, shielding is vital to ensure device performance and user safety. Key applications include:

- Mobile Devices: Smartphones and tablets utilize EMI shielding to protect against interference that could impact device functionality.

- Computers: Laptops and desktops employ various shielding techniques to minimize interference from internal components.

- Wearable Technology: As devices evolve into more compact forms, efficient and lightweight shielding options are critical for user comfort and device functionality.

Healthcare and Medical Device Shielding

Healthcare applications have unique shielding requirements due to the sensitivity of medical equipment. Examples include:

- Imaging Devices: MRI machines require effective shielding to ensure accurate imaging results and patient safety from external electromagnetic fields.

- Monitoring Equipment: Devices that monitor patient health must avoid interference from surrounding electronic devices to provide accurate measurements.

Best Practices for Choosing Shielding Materials

Evaluating Performance Metrics

When selecting electromagnetic shielding materials, performance metrics are crucial. Key considerations include:

- Shielding Effectiveness (SE): This metric indicates how effectively a material blocks electromagnetic waves, typically measured in decibels (dB).

- Frequency Range: Different shielding materials perform better at specific frequency ranges. Understanding the operational environment of the device is essential in material selection.

- Thickness and Weight: The trade-off between shielding effectiveness and added weight is critical, especially in portable devices.

Cost Considerations and Budgeting

Cost plays a pivotal role in the selection of shielding materials. It is essential to balance performance with financial constraints while considering the long-term benefits. Some include:

- Evaluate the total cost of ownership, including manufacturing and potential maintenance costs when selecting materials.

- Consider lifecycle impacts; investing in higher-quality shielding could result in lower failure rates and reduced repairs.

Longevity and Maintenance of Shielding Solutions

The selected shielding material should be durable to withstand environmental conditions such as corrosion, moisture, and temperature fluctuations. Considerations include:

- Regular assessments to ensure the integrity of the shielding material.

- Understand the environmental stressors specific to the application environment and choose materials accordingly.

Future Trends in Electromagnetic Shielding Materials

Innovations in Material Science

Future advancements in material science promise to enhance the effectiveness and efficiency of electromagnetic shielding materials. Research is focused on:

- Smart Materials: Innovations in materials that can adapt their shielding properties in response to varying electromagnetic field strengths are in development.

- Biodegradable and Sustainable Materials: There is an increasing trend toward environmentally friendly shielding solutions that reduce the ecological footprint of electronic products.

Environmentally Friendly Options

With growing environmental awareness, the electronics industry is moving towards sustainable electro-magnetic shielding materials. Research is exploring:

- Utilizing recycled materials in the production of shielding components, thereby minimizing resource consumption.

- Developing natural materials with adequate shielding properties as alternatives to traditional metals.

Emerging Technologies and Their Impact

The future of electromagnetic shielding is likely influenced by advancing technologies such as:

- 5G Technology: The widespread rollout of 5G cellular networks will present new challenges for shielding effectiveness, particularly in high-frequency bands.

- IoT Devices: As the Internet of Things grows, there will be a need for miniature, effective shielding solutions to protect countless interconnected devices.